PersonaGrip Relaunches Industrial Ergonomics – 2023

Attn Journalists: • Hi-Res Images & Logo, Gov't Research/Data, and Eye Candy are located immediately below Press Release copy •

NEW BUSINESS MODEL PRESS RELEASE

CONTACT INFO:

PersonaGrip

Ed Dellis

2973 Harbor Blvd, #314, Costa Mesa, CA

+1.714.342.3020

personagrip@yahoo.com

FOR IMMEDIATE RELEASE & DISTRIBUTION

Covid Helps PersonaGrip’s NEW Industrial Ergonomics Training Programs

Costa Mesa, CA — Thanks to Covid-19, remote tech support is now possible via videochat for PersonaGrip’s decades-proven ergonomic Custom-Moldable Handgrip Technology.

After the 2-Day on-site training teaches tool crib technicians the basics for grip installation and tuning, technical assistance is now a tap away via video chat where Dellis and others can literally show new techs how to solve their design issue using a similar tool on camera. Rising-star designers will emerge in the online forums and can offer assistance, as well.

Different designs are required in shared-tool work environments compared to those used in dedicated-tool assembly lines. PersonaGrip’s unique remoldability allows techs to zero-in on the proper ergonomic fit over a period of time using feedback from the workers. Whether the grip is designed for an individual worker or an entire team of workers, tool crib personnel are taught how to create these ergonomic hand grips from scratch. The second video immediately below (at the end of the Short Version) shows the raw material being applied to a ball-joint separator for knuckle protection:

https://youtu.be/eZ2S_76L33w (Full Video – Ergonomics Training 9:34s)

https://youtu.be/MSWH-ptIoBg (Short Version – Ergonomics Training 4:50s)

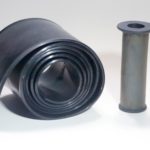

Inventor, Ed Dellis, visits factories and provides the 2-Day Training Program where up to five technicians receive face-to-face training from the inventor himself. Upon completion, factories are then certified to purchase PersonaGrip’s proprietary raw thermoplastic material in coils: 1/8″-thick x 4.0″-wide x 60″-long. The Slip-On Grips are similar to motorcycle grips, and feature the 1/8″-thick moldable layer on top of a non-moldable rubber Santoprene core; they are available in the standard 7/8″ (0.875″) and 1.000″ ID sizes.

Robots & Cobots

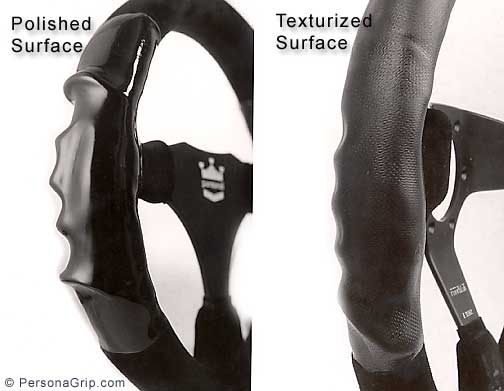

End Effectors on robot arms can now be molded to accept exact contours of the item being handled. By heating PersonaGrip‘s moldable material after a positive attachment to the effector, impressions can be made into the surface that allow non-slip grasping at lower clamping forces due to the leveraging effect created by the impressions. Impressions for multiple items at a single workstation can also be designed into the surface by simply repeating the molding procedure until non-interfering patterns are developed for both items. Once cooled, the shape is retained until heated and remolded again.

Self-Repairing & Grip Tuning

In the event a PersonaGrip ever gets damaged, reheating the surface restores it to its original condition as the material self-welds back together. Oftentimes, through repeated usage, workers discover new ideas for shaping the grips. A reheating process allows the material to be redesigned to whatever shape the worker wants to test. In the event the grip does not work as expected, the grip material can be reheated and returned to its original design.

This infinite remoldability often results in a sense of ownership being developed by each user. In turn, early clients reported that tools were lasting longer on the assembly line due to this Pride of Ownership and extra care.

Post-Training Tech Support

Post-training support comes via the same social media videochat apps that Covid’s isolation taught us to use over the past few years. This provides technicians with direct access to Dellis’ more than three decades of experience where he helped US Olympic athletes win Gold, and drivers win championships in IndyCar, NASCAR, Formula One – both cars and boats including the Unlimited Hydros.

Online communities will develop where trained users can share design ideas with quarterly awards granted for the most innovative solutions.

https://youtu.be/JndKJ10ttTk (ESPN Track Fact at Mid-Ohio IndyCar Race, 1:41s)

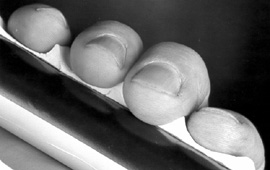

HISTORY

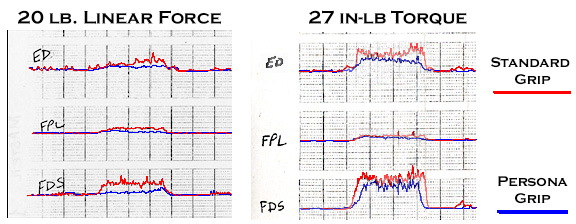

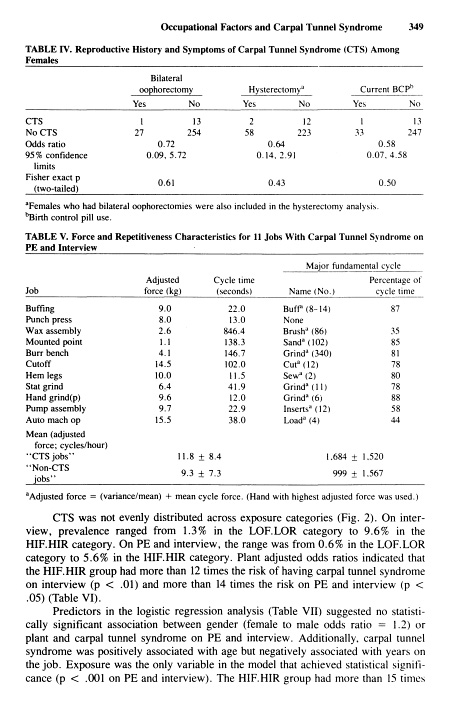

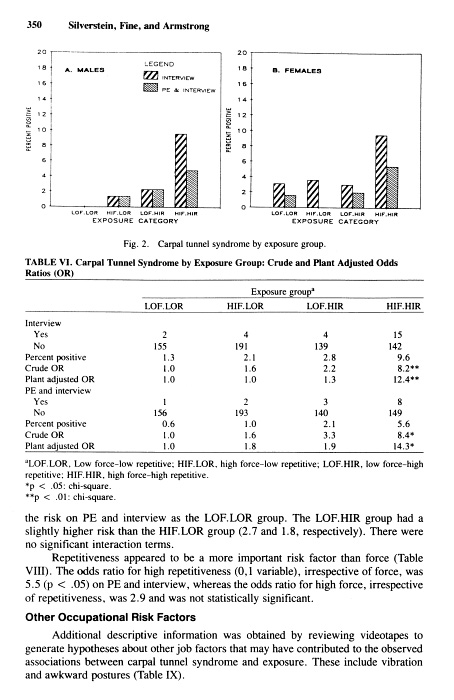

PersonaGrip’s 2-Day Training Programs began in factories across America and Canada in the mid-’90s after NIOSH’s own university-proven EMG tests showed a direct link to preventing repetitive-strain injuries such as carpal tunnel syndrome. These can occur when physically stressed assembly line athletes push their body’s limits for both repetition and force. However, PersonaGrip must be installed and used properly before any benefits can occur. So, tool crib technicians are taught how to ask the right questions to zero-in on the perfect grip solution for a workstation.

PersonaGrip’s early clients for on-site training include: Toyota (USA, Canada, & Japan), General Motors, Ford, Chrysler, Harley Davidson, Kenworth Trucks, Illmore Engineering, Texas Instruments, Hallmark Cards, Rockwell Industries, GoodYear Tire & Rubber Company, Delphi Energy & Engineering, Ciba Vision, Campbells Soup Company, Xerox, Zippo Lighters, and many more.

https://youtu.be/7U-PUse6OFs (Manager’s testimonial at Toyota, Georgetown, KY, 0:51s)

WAKE UP CALL

Proof of difficulty in designing grips properly became apparent to Dellis after he recently received a phone call from IndyCar headquarters in Indianapolis, IN. With patents now expired, they told him that their teams and drivers were now attempting to mold their own steering wheel grips.

Unfortunately, their untutored top wing designs were injuring the drivers’ thumbs since they did not factor the rapid egress needed in the event of a steering kickback after contact with the wall or another car. Regardless, drivers continue to use molded grips to this day due to its improved steering feedback signal which allows them to drive right up to the cornering limit with much greater confidence.

In terms of proprioceptive sensing, the feelings that drivers get in their hands and the reactions workers feel from the tool is akin to putting on a pair of corrective glasses and seeing clearly for the first time. This happens because the reduced stress in the arms improves the signal-to-noise ratio on the feedback signal they’re feeling. Whether that’s steering resistance for drivers that rises and falls predictably as the tire slides past the limit, or tool reactions for workers needing to feel the moment of final torque on a fastener, the relaxed grip improves the feedback.

https://www.steeringwheelguy.com/

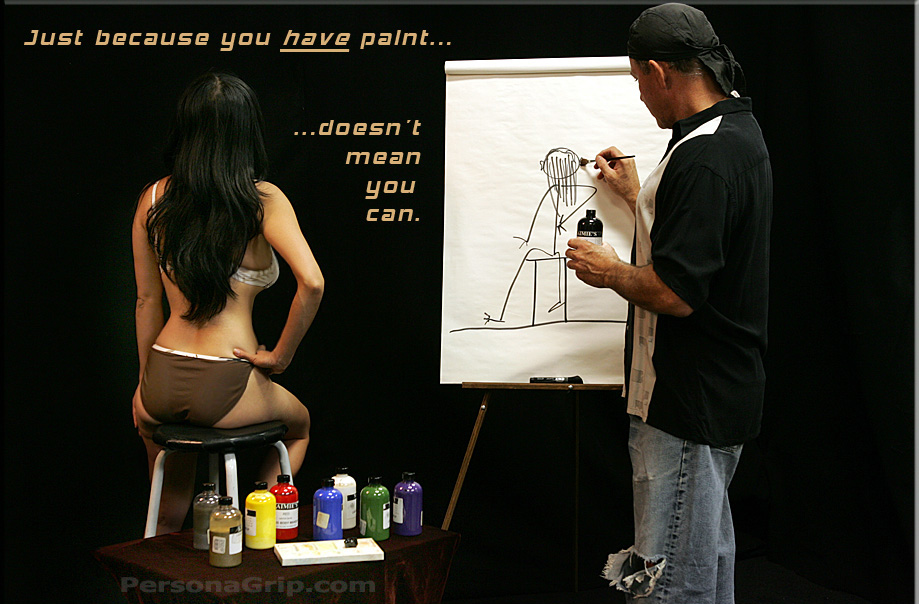

Dellis likens his composite heat-moldable thermoplastic material to artist’s paint, “Just because you have paint, doesn’t mean you can paint.”

Similarly, the hand’s interaction at the HMI (Human-Machine Interface) is much more complicated than it initially appears. Dellis claims there’s both an Art and Science to creating custom shapes that are comfortable while they reduce or eliminate hand fatigue completely.

GOVERNMENT RESEARCH

Independent EMG tests of PersonaGrip on a Lido Work Simulator at NIOSH (National Instituite of Occupational Safety and Health) using standard university test procedures recorded a 54% reduction in effort for sliding, and a 43.5% reduction for torque. According to the scientists, this less-than-half-effort discovery represented a complete paradigm shift in how we interact and control objects around us.

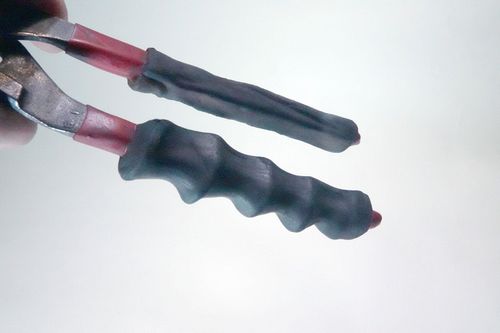

As workers learn more about how their hands interface with leverage-based molded hand grips, they become inclined to reshape and fine-tune the various wings, flutes, flanges and other design elements. During training, tool crib personnel fine-tune the grips until they’re perfect; either by themselves, or with trained assistance.

PersonaGrip‘s training includes three basic opportunities to zero-in each individual design: Installation, Fine Tuning, and Final Treatment.

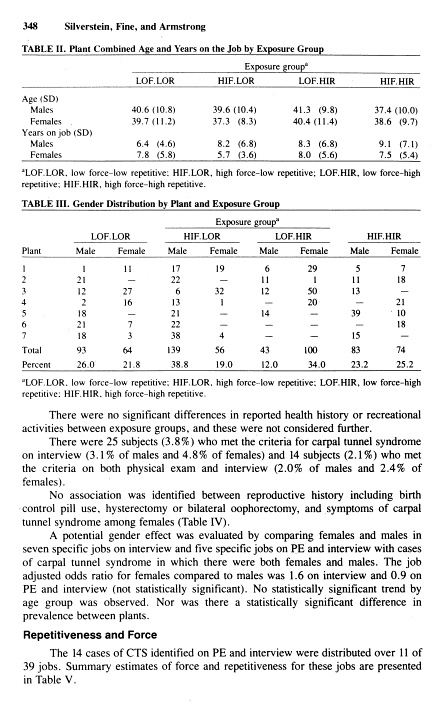

The grip’s frictional release characteristics can be dialed in with different surface treatments. Dellis says, “During PersonaGrip’s early testing and development stages, the sample compounds I received from suppliers felt too much like slippery plastic patio furniture straps. I needed it to feel more like porous rubber with predictable stick-slip release characteristics, not just smooth plastic.”

“You want the grip to stick when grabbed, but release in a smooth, predictable, and controlled fashion. For example, this happens when you relax your grip during micro-adjusting to settle a binding leather glove. Different surface treatments can be used to tailor the grip’s feel after the basic shape is dialed-in, and I cover all of this in the Training Program.” Dellis said.

Designing grips properly is an evolutionary, interactive process.

Dellis continues with a part of his teaching script, “Tool companies are compelled by shareholders to create featureless grips for the 50th Percentile hand size, or they can lose sales. So, their grips are completely generic, passive in nature, and rely mainly on the friction between the glove and grip for control and feedback. This means those generic grips must be squeezed.

The moldable-grip paradigm shift includes video recording each tool in use, and then studying how the hand interacts with the tool throughout the cycle. This leads to designing carefully contoured shapes that rise up off the tool’s generic surface and enable workers to press or “lean up” against them using leverage to gain better control with far less effort. Science proves this.”

The 2-Day Training Program includes enough material to train up to five tool crib personnel at each location.

###

NOTES:

1) ALL Zip Files contain both Plain Text (.txt) and Rich Text (.rtf) files.

2) Zip Files Contain a Full Set of images of the TOOLS in various resolutions including 5000-pixels for Magazine Printing.

3) The BRANDED Full-Res zip has a very faint (barely noticeable) PersonaGrip.com URL at the bottom.

ZIP FILES

High-Res Photos • Research Data • Eye Candy

Tool Grip Downloads are Available in 3 Sizes: 1000 px, 2500 px, 5000 px (branded and unbranded), using links below photos.

1000 pixels , 2500 pixels , 2500 pixels URL Branded

1000 pixels , 2500 pixels , 2500 pixels URL Branded

1000 pixels , 2500 pixels , 2500 pixels URL Branded

1000 pixels , 2500 pixels , 2500 pixels URL Branded

1000 pixels , 2500 pixels , 2500 pixels URL Branded

1000 pixels , 2500 pixels , 2500 pixels URL Branded

1000 pixels , 2500 pixels , 2500 pixels URL Branded

1000 pixels , 2500 pixels , 2500 pixels URL Branded

1000 pixels , 2500 pixels , 2500 pixels URL Branded

1000 pixels , 2500 pixels , 2500 pixels URL Branded

1000 pixels , 2500 pixels , 2500 pixels URL Branded